Engineering Projects

Measuring the Volume of Non-Uniform Objects through Water Displacement

Spring 2025

During my Basic Measurements Lab (ME-4031W), our team was assigned the task of designing an experiment. Our group chose to verify Archimedes principle by using an Infrared (IR) Sensor, alongside a LabView-programmed interface to collect data on volumetric water displacement. The team designed an apparatus to correspond this water displacement to the volume of submerged objects in a manufacturing setting, specifically for verifying the volume and material output of metal-casting machines. Check out the poster by downloading below!

DownloadDrone Airbag - Drone Safety Device

Ongoing

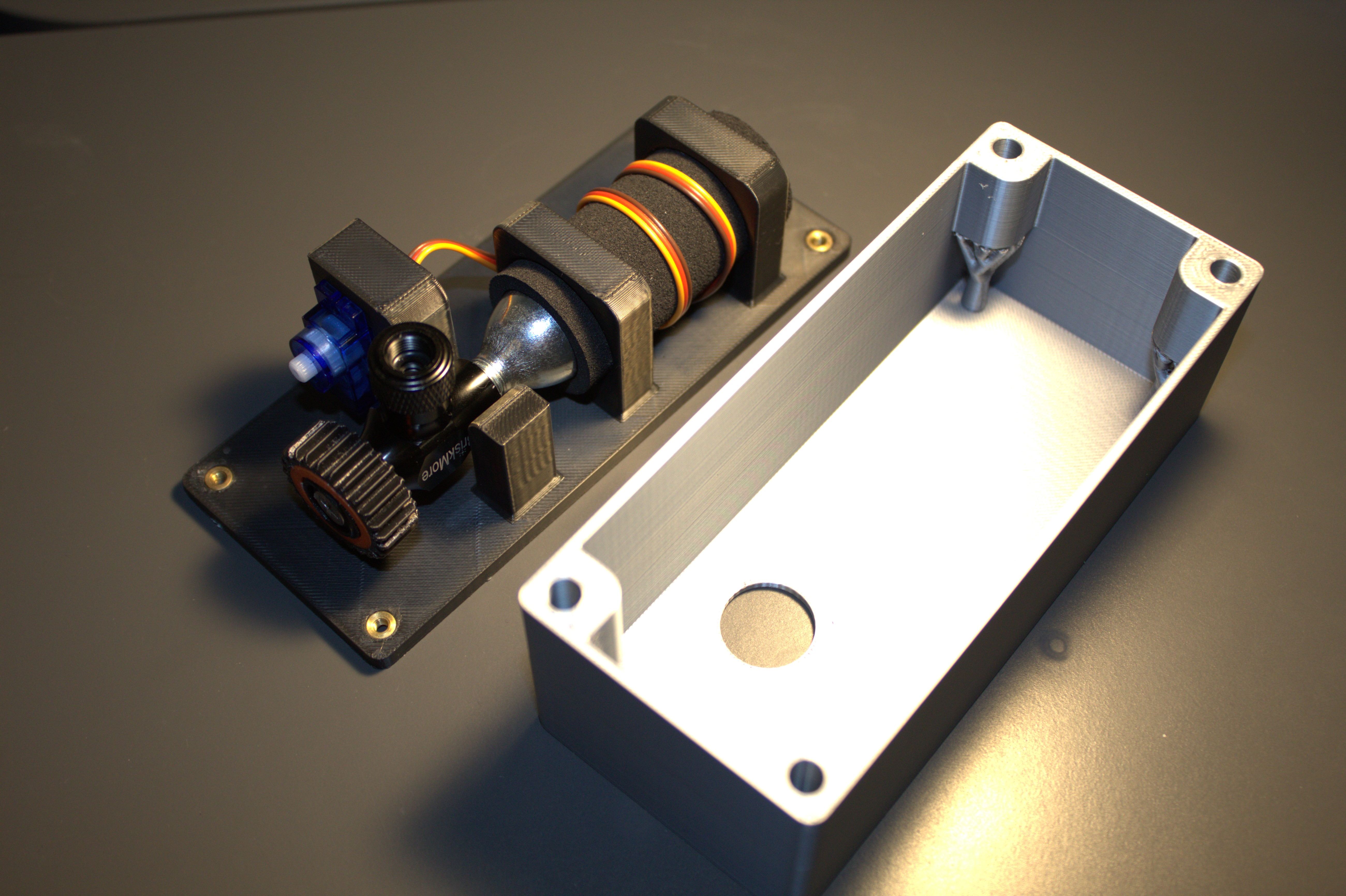

After purchasing my first drone, I encountered several close calls during flights that could have ended disastrously. I often flew over large bodies of water and had near-misses with trees and other obstacles. My solution: develop a "trigger" mechanism to deploy an airbag for a drone. Focusing on design sustainability and compact packaging, I created a casing to house a microcontroller, CO2 cartridge, and servo. Currently, I am developing a method to trigger the gas canister using a barometric pressure sensor to detect altitude changes.

UROP: Detection of Deposition Errors in Conformal 3D Printing using Computer Vision

Winter 2024

This project focused on creating a machine learning-based system to detect errors in 3D printing processes. Using annotated image data labeled with bounding boxes via CVAT, I trained a YOLO object detection model to identify and classify printing defects in real time. The ultimate goal was to improve 3D printing quality assurance by automating the detection of commonly replaced or defective parts.

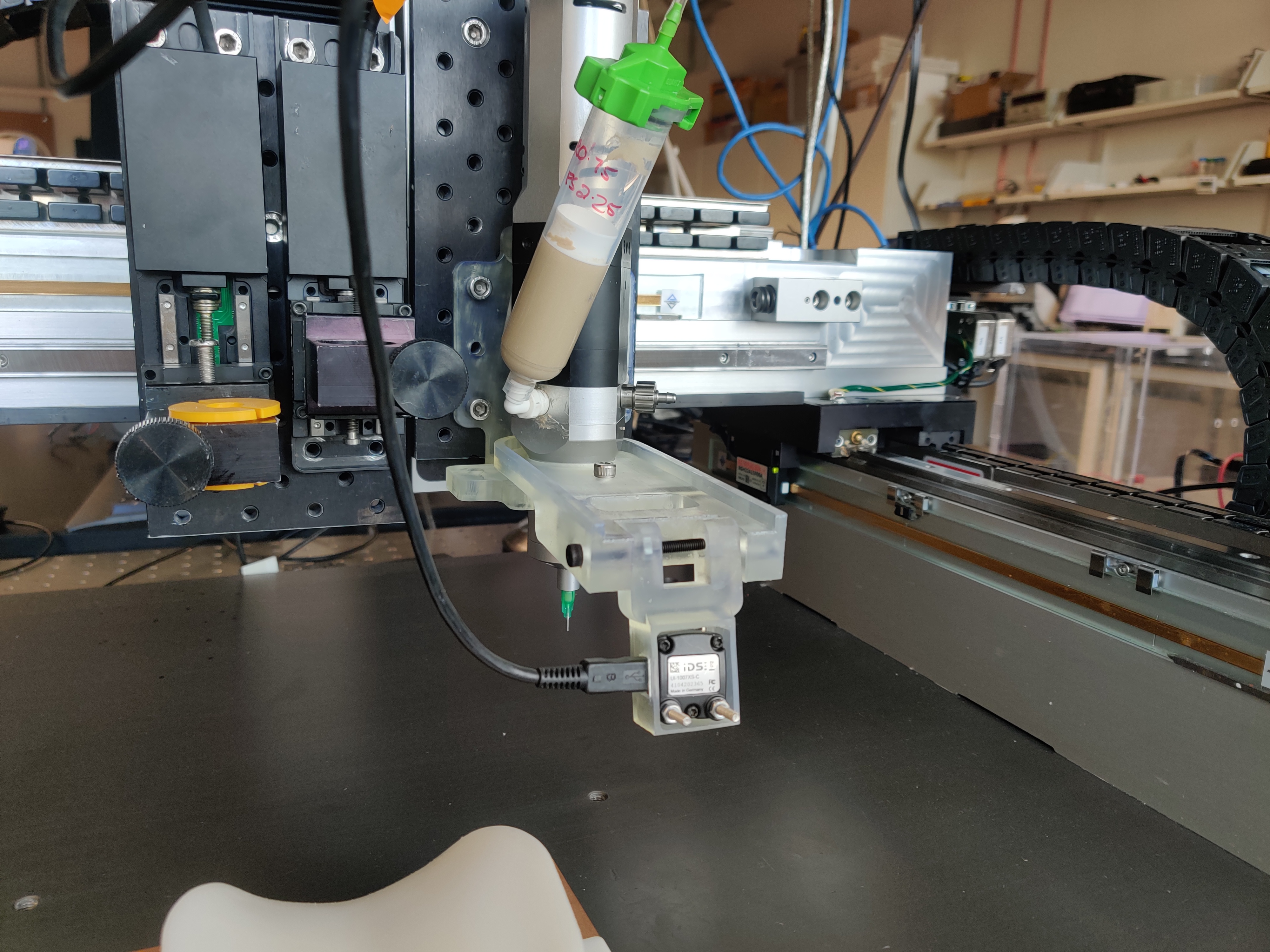

See MoreAerotech 3D-Printer Camera Mount

Spring 2024

When I first joined the McAlpine Research Group, my first project was to design and build a camera mount for an Aerotech 3D printer. The goal was to make it adjustable and vibration-resistant so we could securely film conformal printing in action. The footage was used to monitor the printing process and capture the production of cricothyrotomy training models.

DownloadRaspberry Pi Mini PC

Winter 2023

I took on this project to build up my programming skills and get hands-on experience working with computer hardware. I designed a rugged enclosure for a Raspberry Pi, aiming to use it as a server to host this website. After learning more about the security risks involved, I decided to repurpose the setup for a different application. You can download the design files using the button below.

DownloadSolar Panel Rotator

Fall 2023

For my first professional project, I designed and developed a robot to rotate a solar panel to the optimal angle for maximum solar incidence, increasing energy output. This project taught me a critical lesson about the difference between engineering and tinkering: documenting the process thoroughly. Click the "See More" button below for additional details.

See MoreThe Komarac ("The Mosquito")

Summer 2021

This was one of the first major projects I took on. I decided to build a boat, combining some basic carpentry skills with a lot of persistence. Seeing the Komarac come together from loose planks to a working vessel was incredibly rewarding, and it sparked a deeper interest in how things are built and why they work. It was the first time I really saw myself as an engineer.